Food and Beverage Industry

H2O2 Measurement at Critical Control Points

Food and beverage packaging takes many shapes and forms in today’s marketplace. In an effort to maintain grocery shelf-life and flavour quality, these products are processed and assembled by sophisticated packaging equipment that has evolved away from traditional bottling and canning methods.

Systems of quality control in the food and beverage industry have become more sophisticated as well as companies in the UK, Ireland and US having come under the Hazard Analysis and Critical Control Points (HACCP) guidelines. They call for food companies to develop quality monitoring procedures at critical control production points. Furthermore, corrective actions must be identified and taken if established limits are not met. Lastly, effective record keeping of food safety monitoring must be maintained to document the various HACCP-mandated processes.

HACCP is regulated in England, Scotland and Wales by the Food Standards Agency, and in Scotland by Food Standards Scotland. In the Republic of Ireland it is regulated by the Food Safety Authority of Ireland and based on EC No. 852/2004. In the US it is regulated by the FDA.

Aseptic Packaging

Aseptic packaging technology utilises both hydrogen peroxide and heat to achieve sterility enabling food products to be distributed through ambient temperature channels. FDA approved these processes in January 1981 in response to a petition by Tetra Pak. Within months, some of the largest US beverage producers (including juice and dairy) began employing aseptic packaging sterilisation procedures. Although new to the US at that time, the technology’s origin can be traced to Sweden’s Tetra Brik packaging introduced in 1963.

Extended Shelf Life

The chilled food and beverage segment of the market has boomed since the 1980s as packaging engineers have employed variations on the ‘aseptic theme’ to produce systems that prolong shelf life beyond that of traditional pasteurised products (hence Extended Shelf Life or ESL). Although ESL processes apply a heat/time regimen to the product that is regarded as a sterilisation process, ESL packaging operations do not necessarily sterilise the packages or package enclosures. Therefore all ESL products are distributed through refrigerated channels. Examples of ESL products offered in the refrigerated section of the grocery store are:

|

General Protocols Used in Packaging Systems

Regardless of the food packaging system being considered, packaging vendors apply the same basic microbiological and engineering principles to design their food safety monitoring equipment. Precise details of the processes are dictated by the product type – high acid or low acid (a.k.a. pH). The general procedures used to sterilise either the product, or packaging systems before any product or package enters the system, involve any of the following:

- Steam

- Steam plus hydrogen peroxide

- Hydrogen peroxide

- Peracetic acid

- Other chemical treatments

- Hot water

When chemical sterilisation is applied to package interiors or closures, residual chemical must be removed prior to filling to not only comply with national residual regulations but also to maintain sensory quality and prevent flavour degradation.

Hydrogen Peroxide Measurement, Monitoring and Control

In 21 CFR 178.1005 (a) of the US Code of Federal Regulations, hydrogen peroxide is defined to be a 35% aqueous solution. In subsection (d) of this same standard, it specifies the limits on the hydrogen peroxide residual: ‘No use of hydrogen peroxide solution in the sterilization of food packaging material shall be considered to be in compliance if more than 0.5 part per million of hydrogen peroxide can be determined in distilled water packaged under production conditions (assay to be performed immediately after packaging).’

Analytical Tools for the Detection of Hydrogen Peroxide

The traditional laboratory bench method used to determine hydrogen peroxide levels is a titration with potassium permanganate (KMnO4). This requires volumetric glassware, use of a buret, and standardisation of the KMnO4 prior to testing. Typically, titrations are repeated up to three times to determine an averaged test result. In the manufacturing arena, where it is not uncommon for lines to produce hundreds of bottles per minute, waiting for a lab result to confirm residuals is costly.

Paper hydrogen peroxide test strips offer advantages over titrimetric methods. Typically, a strip is dipped in a sample for a specified time, removed and allowed to stand while a colour reaction develops on the reagent strip. The developed colour is then matched to a printed colour standard. One disadvantage of paper test strips is that they are deactivated by moisture. Care must therefore be taken to prevent exposure of the strips to air.

Even under ideal conditions, hydrogen peroxide test strips have a limited shelf-life. Furthermore, test strips may not offer the sub-ppm sensitivity required for residual testing. Lastly, test results may be influenced by user technique – for example, how vigorously the strip is stirred in the sample, and the degree to which the sample is allowed to drain from the strip once the strip is removed from it.

Case Study

One of the leading milk processing plants in North America has selected the CHEMetrics K-5543 Hydrogen Peroxide Vacu-vials® ampoules and the V-2000 Multi-Parameter Photometer to ensure compliance with this critical residual concentration limit in its high-speed production environment. The plant operates its several production lines in a 24/7 operation with three shifts per day, and performs the testing process every 30 minutes. The system employs Vacu-vials reagent ampoules and the V-2000 photometer.

In evaluating available test methods, the plant required:

- Accuracy and repeatability at low concentration levels

- Easy training of operating personnel

- Rapid test results

- Low cost

The CHEMetrics K-5543 Vacu-vials test system met those requirements.

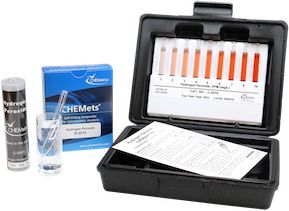

CHEMetrics Hydrogen Peroxide Test Kits

CHEMetrics manufactures a set of innovative, colourimetric hydrogen peroxide test kits that are economically priced and offer:

- Immediate test results (in less than 2 minutes) at the point of testing, not in the lab

- Long term reagent stability

- Sub-ppm sensitivity

- Accuracy independent of user technique

In this CHEMetrics analytical system, the hydrogen peroxide liquid reagent is pre-dosed and packaged in a vacuum-sealed ampoule. CHEMetrics offers a variety of methods and test kit configurations that permit the measurement of hydrogen peroxide concentrations ranging from sub-ppm to percent levels. The analytical method that is most widely used by food and beverage customers for hydrogen peroxide food safety is the ferric thiocyanate chemistry. In this chemistry, the ampoules contain a ferrous ammonium thiocyanate reagent. Hydrogen peroxide in the sample converts ferrous ammonium thiocyanate to ferric thiocyanate. The intensity of the orange-brown coloured ferric thiocyanate is proportional to the hydrogen peroxide level in the sample. Test results are obtained in one to two minutes.

In the visual test kit, the CHEMets® ampoule tip is immersed in the sample, the tip is snapped off, and the sample is automatically drawn into the ampoule. After the ampoule is inverted several times to facilitate mixing, it is compared to colour standard ampoules to obtain a test result. The measurement range for the ferric thiocyanate CHEMets® visual test kit is 0 – 0.8 ppm and 1 – 10 ppm, with a detection limit of 0.05 ppm.

VACUettes® visual test kits are also available in which the ampoules have been fitted with an auto-dilutor tip, thus allowing for measurement up to 1.2% (12,000 ppm) hydrogen peroxide.

An instrumental version of this hydrogen peroxide test kit is also available. The same test procedure is followed except that the ampoule (Vacu-vials®) is read in a photometer rather than compared visually to colour standards. The measurement range for the ferric thiocyanate Vacu-vials® instrumental test kit is 0.15 – 6.00 ppm, with a detection limit of 0.15 ppm.

Another CHEMetrics kit option for measuring high levels of hydrogen peroxide (up to 20%) employs a titrimetric ceric sulphate reagent and ferroin indicator. Titrets® ampoules employ a reverse titration method that employs pre-dosed, vacuum-sealed reagent. The sample is drawn into the ampoule in small doses until a sharp end point colour change signals the equivalence point has been reached. Quantitative test results are read directly from a scale printed on the side of the ampoule.

Lastly, a ceric sulphate Go-No-Go test test kit format is available upon request for situations where a Pass/Fail result at a specified control point is sufficient. A single, small dose of sample is added to a screw cap vial containing the hydrogen peroxide liquid reagent and endpoint indicator. An immediate colour change occurs to signal that the hydrogen peroxide level in the sample is either above or below the specified control point.

Operator training is reduced by more than 50% compared to alternative hydrogen peroxide tests because of the intuitive operation of the V-2000 Photometer and the easy-to-use Vacu-vials ampoules. The CHEMetrics system virtually eliminates false positive results due to operator error. Plant management and quality control personnel have peace of mind knowing that the packaging process is uninterrupted, their products are safely packaged, and they are fully compliant with local and national requirements and regulations.

Food processors must weigh analysis cost, turnaround time, accuracy, sensitivity and ease of use when determining which analytical sterilisation test method suits their requirements. CHEMetrics hydrogen peroxide test kits, with their ‘snap and read’ approach to sample analysis, fulfill each of these requirements with distinction.

CHEMetrics self-filling ampoules have become the industry standard for disinfectant testing within the aseptic packaging industry. They are available in instrumental or visual formats. They are available not only for hydrogen peroxide but also other disinfectants such as peracetic acid and ozone.

CHEMetrics,

Edited by Patrik Askert, Galgo,